METAL ROOFING SHEETS FITTING INFORMATION

Here are some instructions on how to fit your box profile roofing sheets and flashing & guttering. Contact us for more information!

Metal Roofing Supplies Box Profile Sheets Fitting Instructions

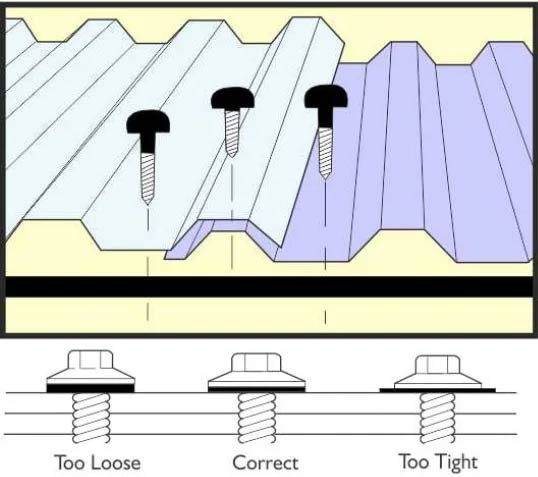

Phoenix Steels’ profiles are easy to install and should be securely fastened with self-drilling screws. Place screws through the troughs for box profiles and tile form sheets, and the peaks for 3″ corrugated sheets. Position fixings on both sides of the lap, with two extra screws through the central trough for maximum stability.

A full range of accessories, including trims, gutters, and fixings, is available on request. Ensure correct tightening torque is applied to all fasteners for a secure, long-lasting installation.

WhatApp our team to get Faster replies & pricing for your projects!

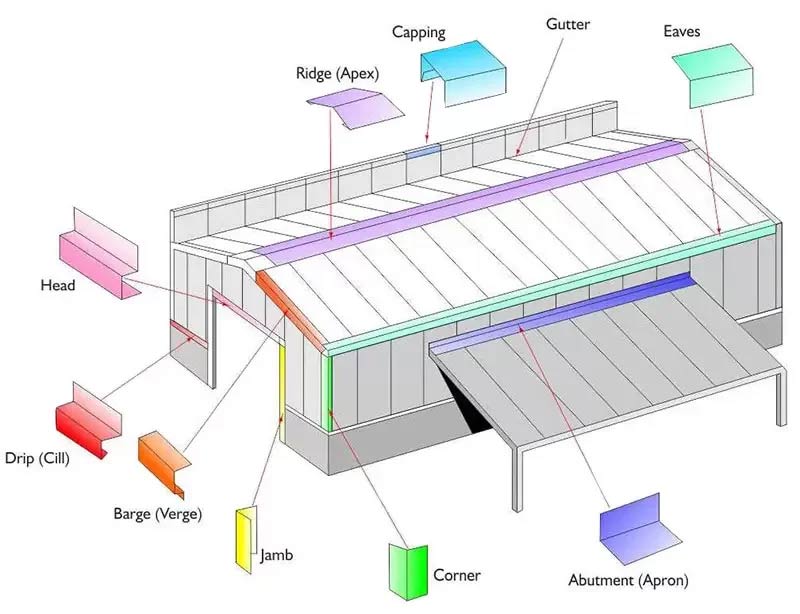

All flashings are custom-made to customer specifications, available in a full range of colours and finishes, with lengths up to 3 metres.

For enhanced rigidity and safer handling, we recommend specifying welted edges to eliminate sharp edges.

Secure flashings using stitcher screws, spaced at 400mm centres for roof slopes under 15°, and 450mm centres for slopes over 15°. Vertical flashings should be fixed at a maximum of 450mm centres. For single-span roof or wall constructions, stitching should be at maximum 300mm centres.

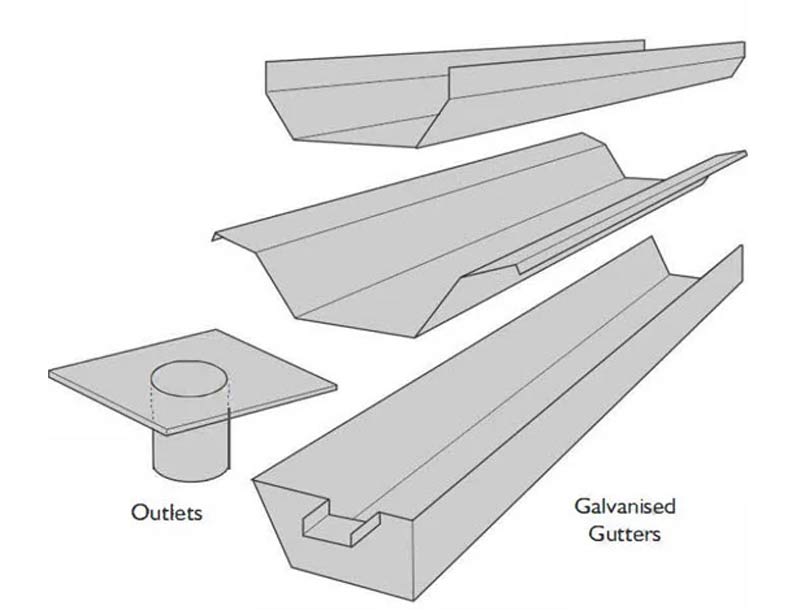

Before starting installation, verify that all supplied components—gutters, downspouts, brackets, and fittings—are correct. Using a chalk line, measure the roofline and mark a gentle slope of 6mm per 3 metres towards the downspouts. Plan downspout placement to align with the existing drainage system.

Begin by installing brackets, marking their positions along the fascia every 600–900mm. Fix them with screws, ensuring alignment with the marked slope. Place the gutters onto the brackets and secure them using clips or screws, per the system’s instructions. Apply gutter sealant at joints if needed to prevent leaks.

Next, fit the necessary components. Secure end caps and outlets, ensuring proper sealing. For multi-section systems, join sections with supplied connectors, fastening with screws or rivets as required.

For downspouts, connect them to the outlets and add elbows to direct water flow. Fix downspouts to the exterior wall with brackets every 900–1200mm, ensuring water is channelled away from the foundation.